Today, I’m going to be showing you how to do a scratch test on a compressor. And this is to prove that the compressor is indeed bad, so you’re not unnecessarily replacing a compressor when it’s not bad. This is a fairly simple test.

What you want to do is go ahead and pull your disconnect and then discharge your capacitor, touching only the insulated portion of the screwdriver, bridging the leads. I think it good practice just to go ahead and discharge all the capacitors. I’ve got a video showing how to secure a dangling capacitor and make this a little safer.

Anyway, then what you want to do is go ahead and disconnect all the leads to the compressor, noting where they go. I pretty much know my system’s common is black, red is for run, and yellow for start, on the S. But if you need to write this down, go ahead and write it down or take a picture so that you can remember. Then go ahead and pull your leads off.

Once all leads are disconnected, then you’re going to do what’s called a scratch test. Go ahead and scratch off a place on the compressor, usually on the top, so that all the paint is gone on that top portion. And then what you’re going to do is set your volt meter to ohms. So I’ve got my volt meter here, and setting it to ohms.

Verify that your volt meter is working properly by touching both of the leads together, like so. You should get a full sweep of the needle, showing zero or close to zero resistance. So this is pretty close, here.

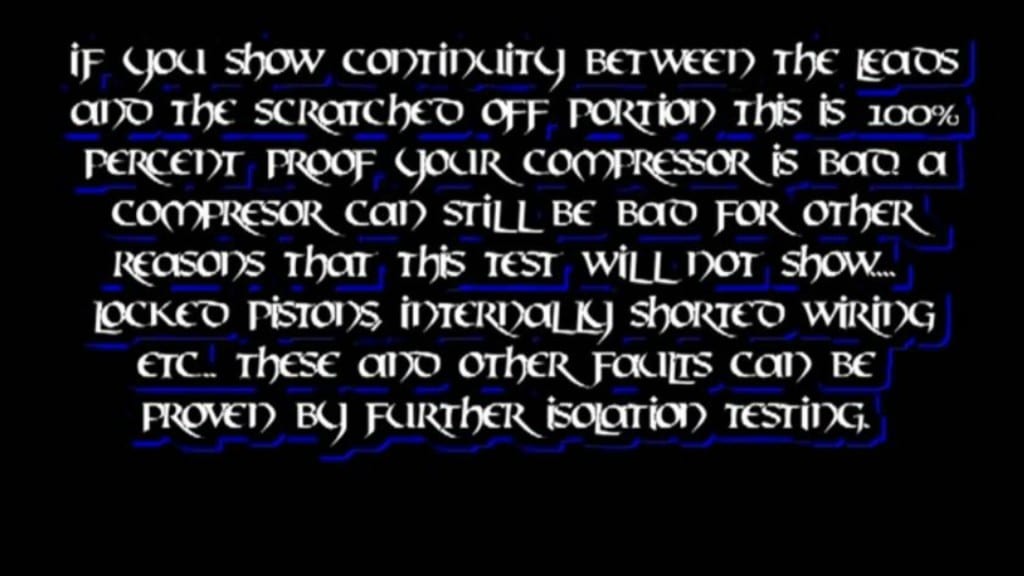

And then what you’re going to do is go ahead and put one lead on your common terminal, or any of the terminals. And then the other lead, you’re going to put on the space that you’ve scratched off on the top of the compressor. And you’re going to go to each of the leads, testing.

And what you’re doing is making sure that a wire hasn’t ground out on the compressor. And this one is showing that nothing’s wrong here. I’ll try to get you different view of this, here. I’ll show you the compressor here. So I’ll go ahead and set it to a higher ohm reading.

So you can see, you’ve got zero resistance there. We’re going to test to the lead, and then to the spot that we wore off of the compressor. And to each of the three leads. And according to this, we’re OK.